II. Ukrainian Doors Market History

GOLDEN TIMES.

At the beginning of the new decade (2010), the idea of covering doors with PVC film came from China. At this point, the idea of the film was also very timely. The fact is that at the same time, several explosions occurred, which once again completely changed the vector of market development, and we are still feeling the consequences of this explosion.

First, and most importantly, the technology of stile and rail doors came and quickly spread from Italy. It allowed to make more combinations of door styles, and simply to make them faster.

Secondly, vacuum presses appeared that allowed covering the relief surfaces of door panels (including "Canadian" ones) by PVC film.

Thirdly, this period coincided with another boom, namely, the boom in construction and quantity increase of construction hypermarkets in Ukraine: "Epicenter", "Nova Liniya", "OBI", "Praktiker", "Leroy Merlin", "OLDI", "Budmax" and others were competitors who needed to fill their trade networks with goods in such a way that the buyer had the feeling that the shop windows were as full as possible. This required a very large number of doors, profiles, and jambs. For example, only in the "Epicenter" trade network (even before the history of the takeover of Novaya Liniya there were about 25 markets), the remains of doors and decorative products amounted to more than 10M US dollars.

Fourthly, is the formation and rapid growth of exports of products from Ukraine to various countries. Kazakhstan imported especially a lot (about 50% of all exports). Kazakhstan itself was experiencing a construction boom and it needed doors that were better than Chinese ones (at that time the CIS worked more or less and gave preferences to Ukrainian manufacturers).

All these four huge factors have led to the boom of PVC film in the matter of its use in the production of doors and other products. From that moment on, PVC film was everywhere: in "paper doors" instead of paper, in "Canadian" doors, raised panels doors, stile and rail doors, and simply in flat doors. It rapidly pushed "paper" out of the market and occupied an ever greater and greater share of sales. But, it would be impossible without the purchase of additional special equipment.

Purely technologically, PVC film requires the use of another glue - polyurethane (PUR), instead of PVA for paper. And it changes everything!

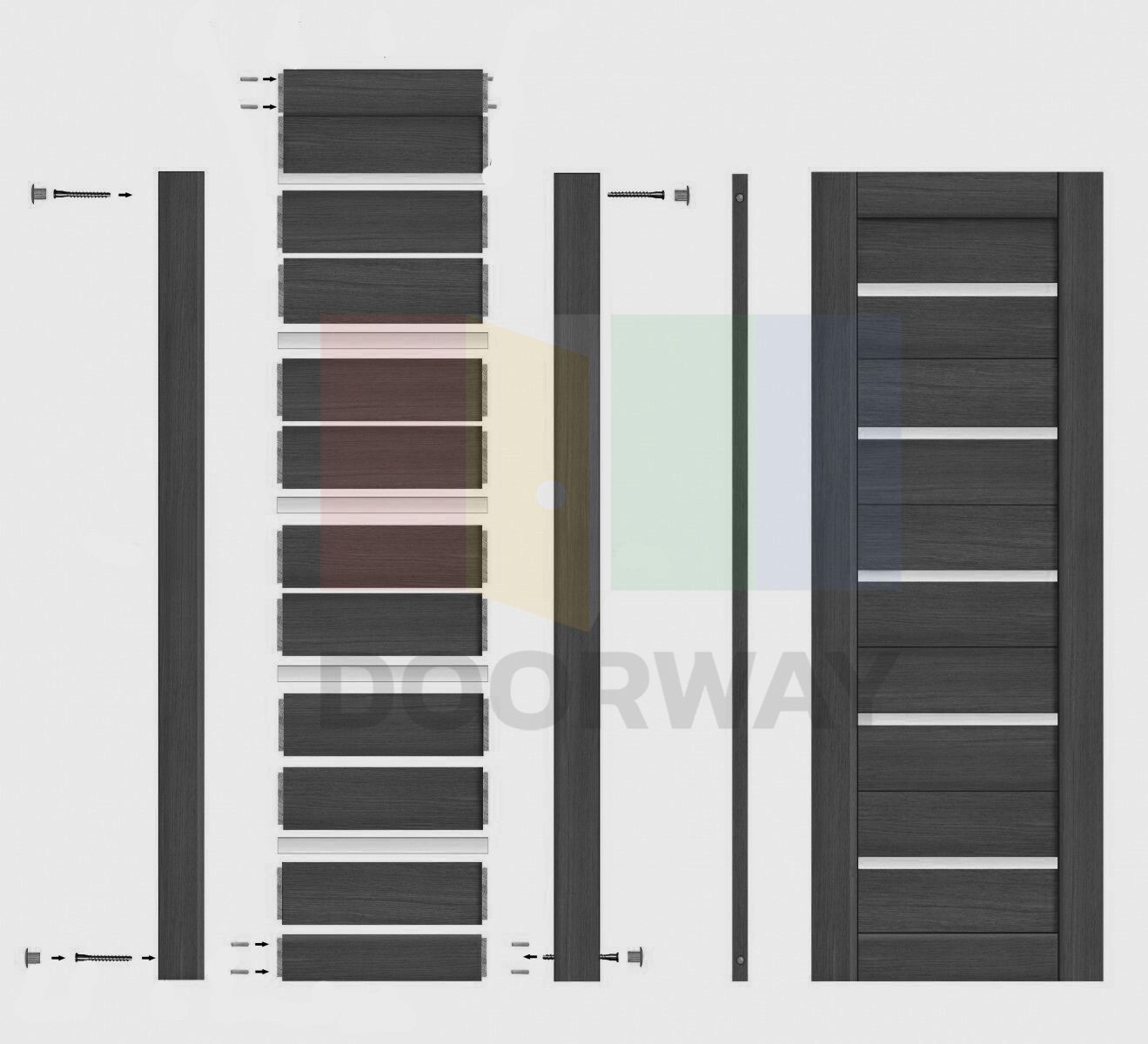

So, the new equipment for wrapping elements of stile and rail doors, such as jambs, moldings, architraves, etc., costs approximately EUR 250K per unit (pictured), and several of these are needed.

In addition to these machines, a whole list of other expensive machines is additionally required: CNC milling centers (from EUR 150K), 4-sided planer machines from EUR 70K, saw-end-matching machines, panel presses, packaging machines, etc.

All this was bought in the same "golden times" of super sales, where the margin was more than 50% on full door & profiles kit. It was a very good profit that allowed them to buy anything.